Radical Dry Rufino XS peeler

Cutting capacity: 400-600 kg /h Dry

Available in 2 sizes:

RADICAL DRY RUFINO XS (400-600KG/H DRY)

RADICAL DRY RUFINO XL (800-1000KG/H DRY)

Manufactured entirely in Spain with top quality European materials.

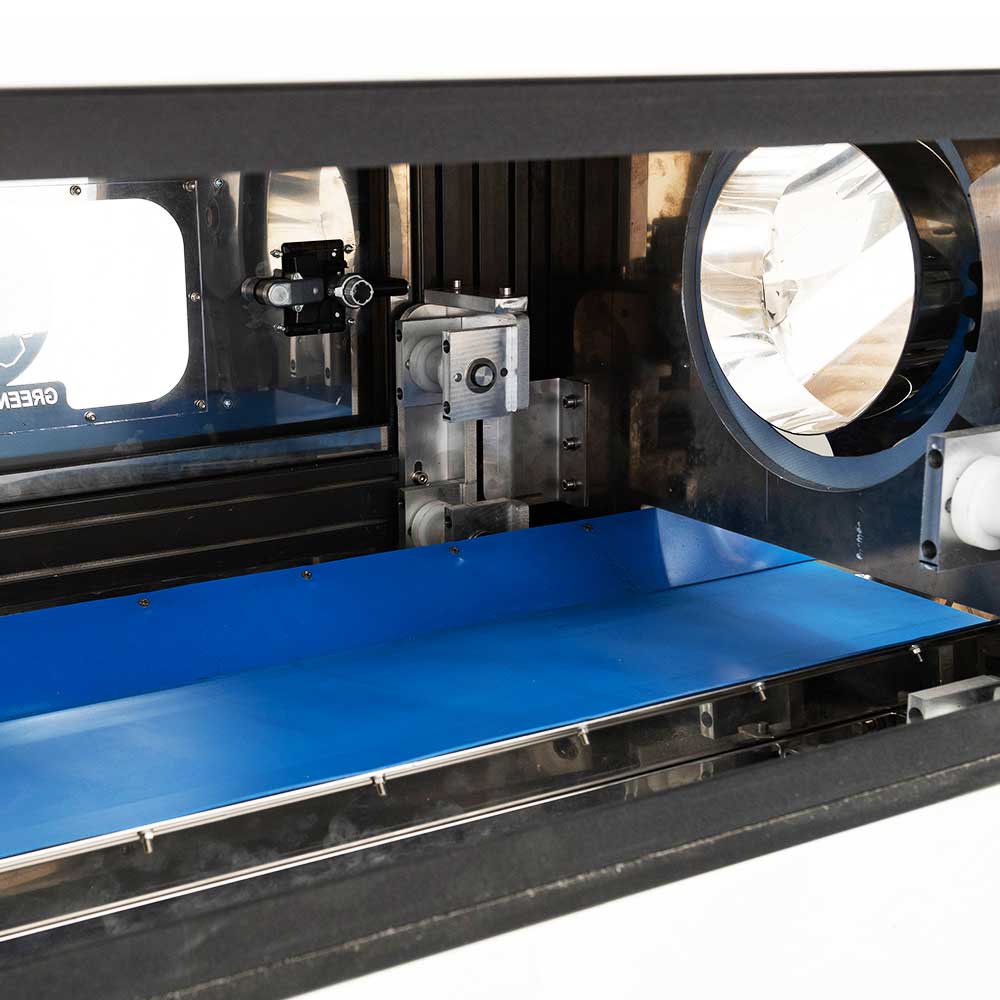

This is the most advanced device on the market and offers three machines in one. Firstly, there is the dry manicuring station, secondly, all the biomass passes to a second chamber where a dry extraction is carried out with the remains generated after pruning, thirdly, CO2 can be injected into the chambers, both to speed up the manicuring and to obtain more performance in the extraction of hash.

It also incorporates software that allows the speed of both drums, injection times and number of CO2 cycles to be controlled, as well as the working speed of its conveyor belt. It also allows the registration of different users to know at all times the performance obtained by the different work groups operating with our machine.

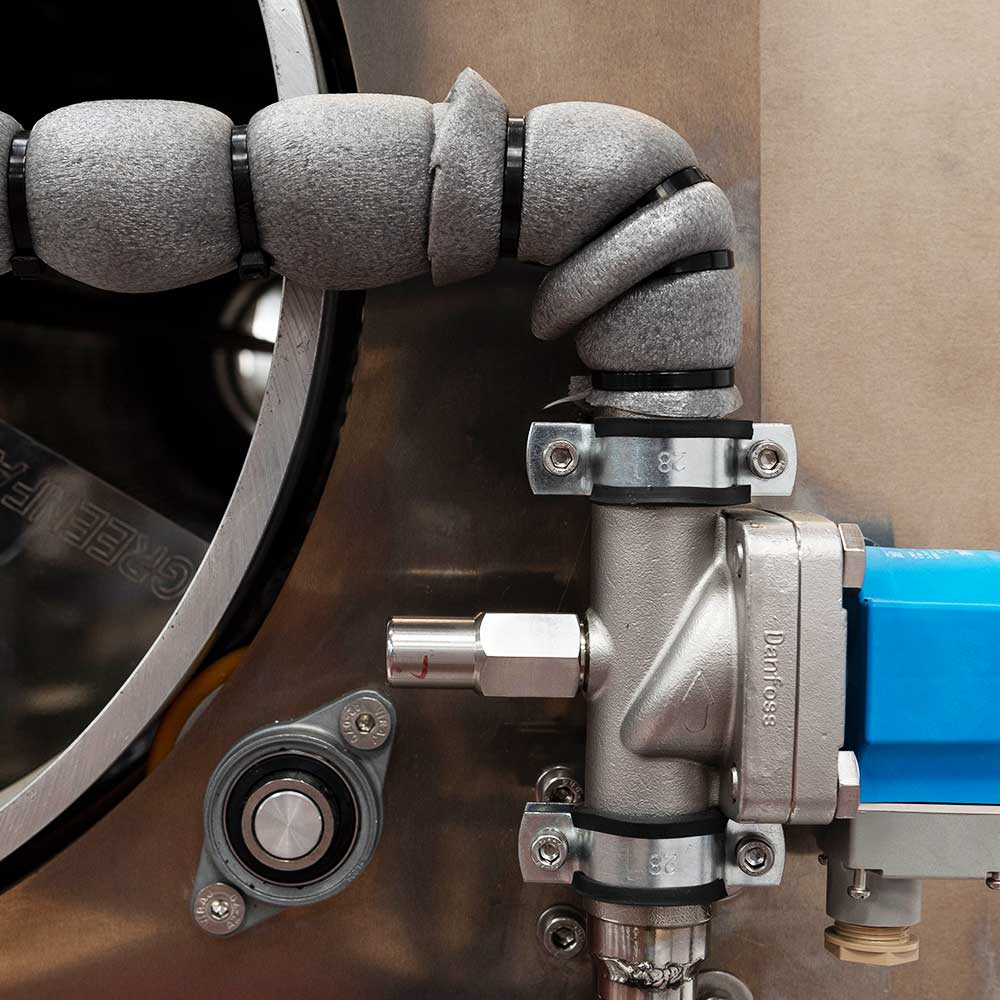

Its structure is made of high quality duraluminium (AL5083) for its skeleton and front plates and stainless steel (AISI 304) for its protective covers, doors and both drums.

(AISI 304) for its protective covers, as well as doors and both drums, the latter with non-stick treatment.

An industrial device at the forefront of technology.

Its design allows quick access to its interior for fast cleaning and maintenance, as well as incorporating locks so that only authorised persons have access. It also has transparent windows so that you can keep an eye on what is happening inside at all times.

Its blades are made of food-grade polyethylene to ensure that they comply with quality standards and do not contaminate our flowers at any time.

All our machines leave the factory tested and adjusted, so you only have to worry about connecting it and start working (PLUG&PLAY).

Easily transportable with its wheels and fastening and support elements, to be able to load it comfortably in our vehicle.

We offer this type of device fully configurable (our end customer can decide the number of conveyor belts he wants, the brand of engine he wants to mount, among others).

When it comes to cleaning it, we will use a pressurised air blowing machine to remove the minimum residue that we can find inside with a sponge, hot water and soap, degreasing spray or isopropyl alcohol.

Whenever we clean our machine, we should always grease all the rolling elements with a spray grease.

WE ARE SPECIALISTS IN THE PROCESSING OF LARGE AREAS OF LAND AND OUR MACHINES ARE DESIGNED TO WORK 24 HOURS A DAY WITHOUT INTERRUPTION.